What Electric Drive Is

There are many definitions of electric drive and associated concepts – electromechanics, mechatronic. Generally speaking, electric drive is a system which comprises mechanical actuator driven by electric motor with proper power electronic converter, equipped with a control system, which, in turn is often a part of automation system.

Nowadays, almost all machinery in industry is driven by electric motors. Domestic appliances, vehicles – trams and trains, electric cars, aircrafts, lathes, cranes, pumps, fans and compressors, air conditioners, washing machines and refrigerators, printers and scanners – everything is equipped with electric drives.

More than 60% of electric energy in average industrialized country is converted into motion by electric drives - from tiniest drives in wristwatches to those monsters with electric motors as big as two-story building.

Modern electric drives:

- have semiconductor converters to regulate speed;

- employ microprocessor-based control systems

- commissioning and tuning of variable speed drives with digital control systems (frequency converters, soft-starters, thyristor converters)

- programming and seting-up modern automation devices (programmable logic controllers, digital controllers, various sensors)

- design of production lines with CADs

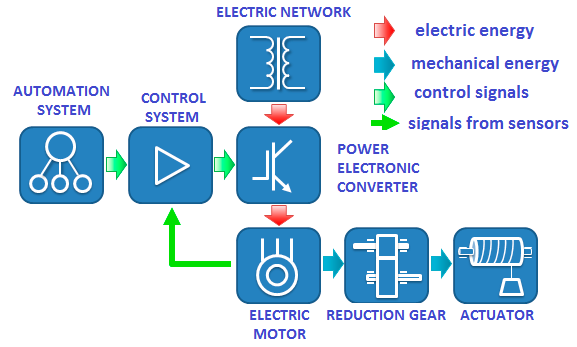

Block-diagram of modern electric drive of industrial mechanism

Electric network is where electric energy comes from.

Power electronic converter is used to control the energy flowing from the network to electric motor. The converter regulates the speed of electric motor. Modern converters are built with powerful semiconductors. Most often, these converters are frequency converters or rectifiers.

An automatic control system is a part of converter. It is a microprocessor-based system, programmed to regulate motor’s speed.

Electric motor converts electric energy into mechanical. Conventional electric motors rotate, but besides there are so-called linear motors, which have linearly-moving rotors.

Reduction gear, or gearbox is used to vary mechanical parameters. Most often, it reduces the speed but increases the torque. Sometimes it transforms rotational motion into linear.

An actuator is a mechanical device that actually performs the work 😀 (lifting something, moving a vehicle, rotating fan etc.)

Automated control system is an industrial computer or programmable logic controller (PLC) that commands the machinery. It implements technology by controlling the mechanical speed. The speed command, or speed reference is then given to power electronic converter.

An electric drive engineer generally deals with controlling electric motors. The following skills are demanded from electromechanical engineer:

Fields of usage of electric drive