PID-control

Control quality

Controllers and feedbacks are attached to systems in order to improve the quality of process control, or simply, the control quality.

Before starting to improve something, it is important to ask yourself “What are we trying to improve?”.

The following table classifies the control quality criteria.

| Static | Dynamic |

|---|---|

|

|

|

|

|

|

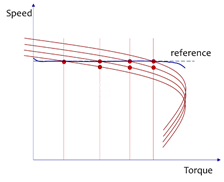

The static performances are pretty obvious: we need minimal mismatch between the given and actual values, thus minimal error. The system is not smooth when the control principle allows only discrete setting of e.g. drive speed. The control range refers to the ratio of minimal and maximal values that system is able to achieve.

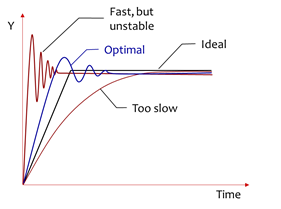

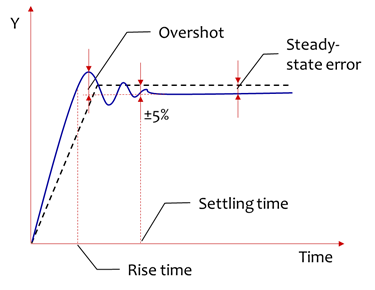

The diagrams illustrating dynamic criteria have time as X-axis. So, dynamics is about how fast the system can get into the desired state and how exactly the process evolves in time. They also describe the shape of the transient curve.

An engineer can estimate the quality at a glance, telling how ‘good’ or ‘bad’ the system is tuned. But preferably, there should be a certain measure of quality, or quantitative indices. Those are illustrated in the diagram below.

The Y-coordinate is typically speed, position, temperature, pressure etc.

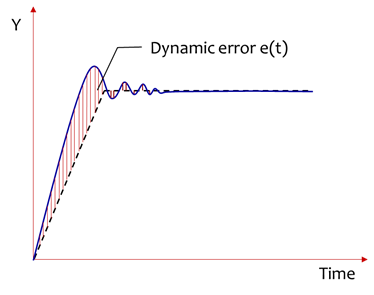

Learn more: dynamic error

\[IAE = \int^{\infty}_0{\lvert {e(t)} \rvert dt}\] Integral of absolute error \[ISE = \int^{\infty}_0{ [{e(t)} ]^2 dt}\] Integral of squared error \[ITAE = \int^{\infty}_0{t \lvert {e(t)} \rvert dt}\] Integral of time multiplied by absolute error \[ITSE = \int^{\infty}_0{t [{e(t)} ]^2 dt}\] Integral of time multiplied by squared error

PID components and transients

In general, controllers of dynamic systems contain three components:

- proportional (P),

- integral (I), and

- derivative (D).

Thus, PID-controller.

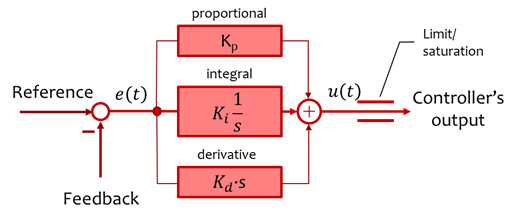

The mathematical expression of the controller’s output is

\[u(t)=K_p e(t) + K_i \int^t_0{e(t) dt} + K_d \frac{de(t)}{dt}\]where \(e(t)\) is the error value, the difference between the desired setpoint and the feedback (actual process value).

Consider that in real applications the output is always limited to a certain value.

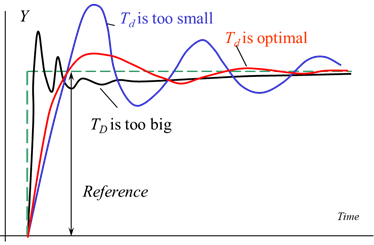

By tuning the three coefficients Kp, Ki and Kd it is possible to improve the control quality.

Learn more: the PID controller theory

It is necessary to understand the behavior of the system, its reaction to each of the three P-, I- and D- terms.

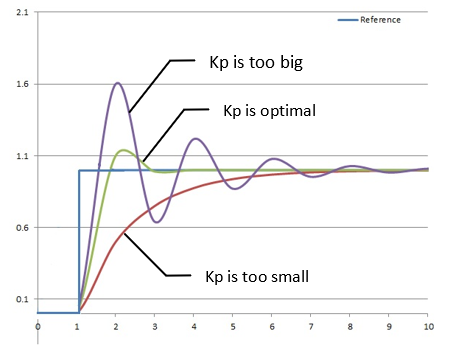

Proportional gain

| Idea | Just take the input error signal \(e(t)\) and multiply it by Kp |

| Effect |

|

| Specifics | It can only work if the error \(e(t)\) is non-zero |

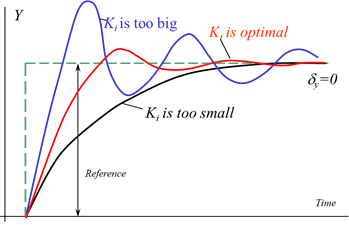

Integral gain

| Idea | This component accounts for the past values of the input signal and integrates them |

| Effect |

|

| Specifics | Can work even if \(e(t)=0\) |

Learn more: why systems with integral component are called ‘Astatic’?

‘Astatic’ means there is no steady-state (‘static’) error. It is because an integral of a function is

\[\int{e(t)dt}=E(t)+C\]Even if \(e(t)=0\)

\[\int{0 \cdot dt} = C\]I.e. the integral component of the regulator will keep producing the output signal even if the error on its input is zero.

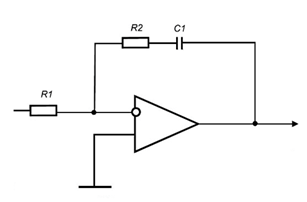

In analog control systems with differential amplifiers it is the capacitor that holds the charge and thus providing the output voltage even if the input signal is zero

Derivative gain

| Idea | The derivative (or differential) component tries to predict the future values of \(e(t)\) basing on its rate of change and acts according to it |

| Effect |

|

| Specifics |

|

Summary on P-, I-, D-

| Parameter | Increasing the P-, I-, D- parameter results in | ||||

|---|---|---|---|---|---|

| Rise time | Overshoot | Settling time | Steady-state error | Stability | |

| Kp | Decrease | Increase | Small change | Decrease | Degrade |

| Ki | Decrease | Increase | Increase | Eliminate | Degrade |

| Kd | Minor change | Decrease | Decrease | No effect in theory | Improve if Kd is mall |

The animation below (taken from here) illustrates how the P-, I- and D- components change the step-response

Learn more: Quantitative methods of PID-controller parametrization

The above given recommendations help you understanding the behavior of the system. You can anticipate the response of your system onto the change of controller’s gains. In 99% of cases in the real life, engineers tune their systems manually.

However, tthe control engineering theory has lots of approaches for the a priori (which means ‘before experiment’) calculation of the optimal PID gains.

The following table summarizes the most common methods.

Method Advantages Disadvantages Manual tuning Doesn’t require the knowledge of the control plant’s parameters You can damage the machinery by exceeding the permissible output values Ziegler–Nichols [b] Semi-experiment method. Simple and robust Aggressive tuning, you can damage the machinery by exceeding the permissible output values Tyreus Luyben Proven method Aggressive tuning, you can damage the machinery by exceeding the permissible output values Cohen–Coon Good process models. Some mathematics; only good for first-order processes Åström-Hägglund Can be used for auto tuning; amplitude is minimum so this method has lowest process upset The process itself is inherently oscillatory